As manufacturers report record years, this organization is preparing them for the future

Jan. 31, 2022

This paid piece is sponsored by South Dakota Manufacturing & Technology Solutions.

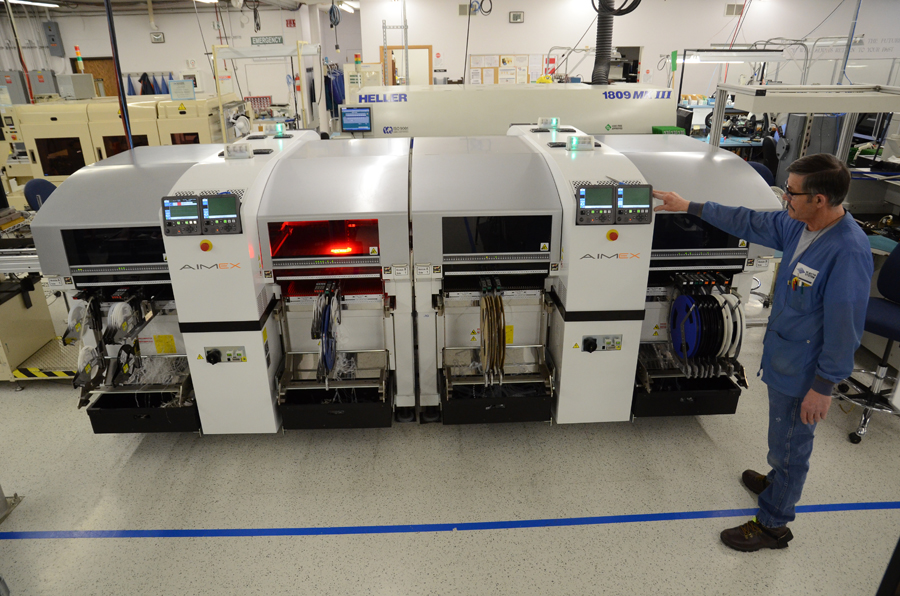

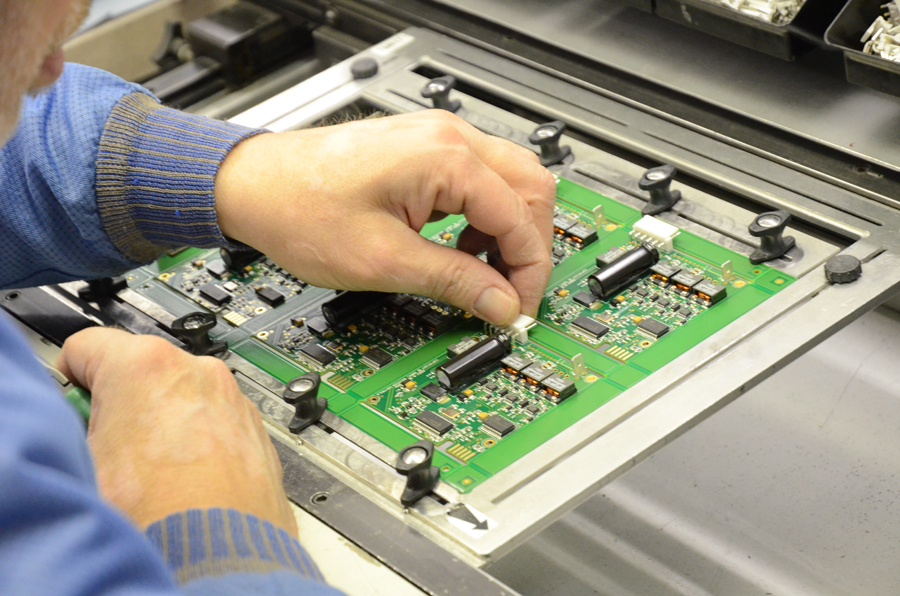

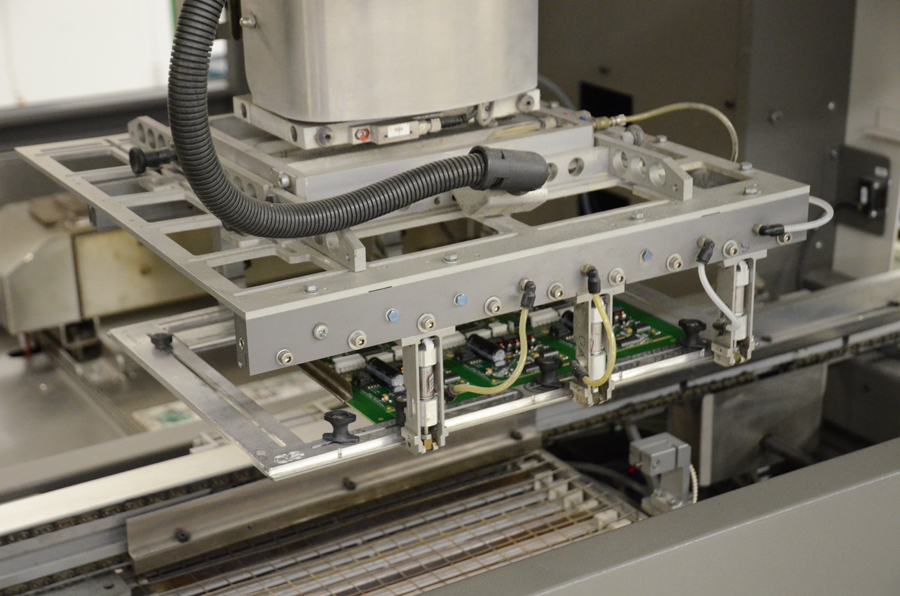

On one side of South Dakota, Electronic Systems Inc. is manufacturing cutting-edge electronics products in Sioux Falls for clients worldwide.

Across the state in Rapid City, B9Creations LLC is designing, building and selling high-resolution 3D printers.

But both they and hundreds of other manufacturers look to the same place for guidance with everything from lean practices to automation strategies: South Dakota Manufacturing & Technology Solutions, or MTS.

“We count on them to help us improve our capabilities and knowledge,” said Scott Reisenauer, chief operating officer of B9Creations.

“I think we’re all probably in growth mode. Manufacturers in South Dakota tend to have resiliency and adaptability and a positive business climate for growth. And what I enjoy about MTS is they’re focused on the things that are significant and important for manufacturers to grow.”

MTS was formed in 2012 as an evolution of Dakota MEP, the federal Manufacturing Extension Partnership. It is federally and state funded, housed organizationally under the University of South Dakota Beacom School of Business and operates out of the Startup Sioux Falls building with additional offices in Rapid City, Aberdeen and Watertown.

“Our mission is to help manufacturers prosper and grow, and our mantra has been that we want to help out with any manufacturing problem you have,” said director Don Cuperus, who has led the seven-person team the past two years.

“We want to be that one place to go that will find you a solution for whatever it is you need.”

For ESI, which was formed in 1980, it has been a decadelong relationship.

“We started using them as a resource mainly for manufacturing improvements and lean, which we really embraced,” president and co-owner Gary Larson said. “We used them extensively for onsite consultations and resources. Most of the time when you engage with consulting services, it gets quite expensive, but this is a very economic model and a very effective one.”

As a public-private partnership, MTS leverages its public funding to offer its services affordably to the businesses that contract for them.

“They come in and review and make recommendations, and you work directly with their team,” Larson said. “They’re fully engaged, helping track changes and execute with you.”

For ESI, embracing lean methodologies has been key in supporting growth. The company has 250 employees and has shifted throughout the pandemic into areas such as pursuing medical device manufacturing and navigating supply chain disruption.

It culminated in the company being honored with the highest overall customer rating and the Service Excellence Award sponsored by leading trade publication Circuits Assembly.

The designation reflected the highest score in all categories, from quality to technology, value for price, responsiveness, dependability and timely delivery.

“Lean enables us to be so much more flexible and responsive to our customers’ needs,” Larson said. “Despite the chaotic nature of 2021, it was a record year even with all the disruptions and obstacles.”

At B9Creations, which employs nearly 50 people, the company’s precision 3D printers and related parts are used in industries ranging from medical and dental to aerospace, industrial, jewelry and beyond.

In partnership with MTS, the company now offers an introductory in lean manufacturing course to its entire team.

“What you learn is it’s a tool set that can be applied to any part of the business. We consider it a core competency for all our employees, from the receptionist and accounting all the way through manufacturing,” Reisenauer said.

“It fits our culture, which is all about continuous improvement, and it resonates strongly because additive manufacturing is always adapting, developing and changing. The technology we produce has to as well, and our people internally have to support that.”

The pandemic has led to rapid growth for the company, he said. With trade shows shut down, “that turned out to be a blessing,” Reisenauer said. “All of a sudden, you get judged on your technology and capabilities and not how big your booth was, so that gave us an opportunity to have customers like Medtronic and others sing our praises.”

Both Larson and Reisenauer also serve on the advisory board of MTS, so they’re eager to get the word out to other manufacturers about the opportunities that exist.

“It’s not a one-size-fits-all approach. It’s how do we tailor and meet the needs of your company,” Reisenauer said. “We used MTS recently on a sales process to bring standardization and grow our sales funnel, so there are a lot of tool sets.”

MTS typically begins with a free business assessment that can be used to benchmark a manufacturer to thousands of peers, including those considered best in class.

“From there, we help identify opportunities – what they do well, what they can improve, and we help work with them and develop a plan,” Cuperus said. “Our organization has a lot of new faces and new services coming, so they will provide a fresh look at everything from automation to marketing, finance, supply chain and operations.”

Manufacturers work with MTS for anything related to operations, including finance, sales and human resources.

Of the state’s estimated 1,100 manufacturers, “we engage with 50 to 60 percent of them each year,” Cuperus said.

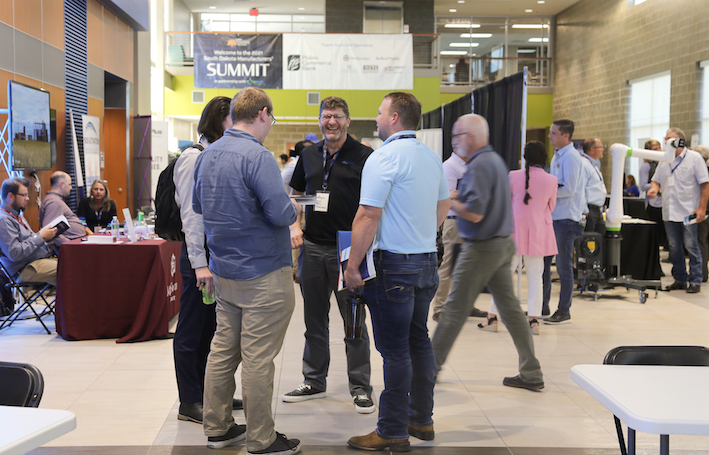

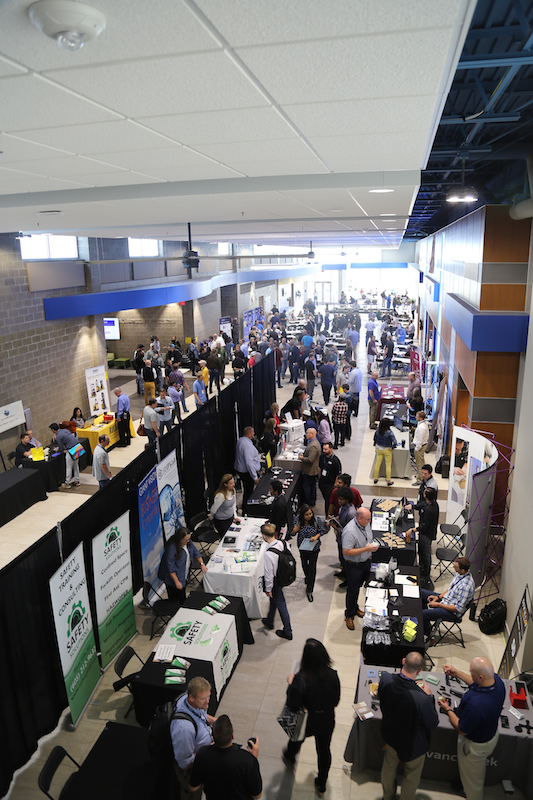

“The largest way is through our annual Manufacturing Summit, in addition to webinars and other events. We also speak throughout the state, everywhere from chambers of commerce to college classes and many different organizations.”

Manufacturers increasingly are looking for guidance around workforce issues, supply chain, automation, leadership training, process improvement and employee engagement.

MTS’s Lean Leadership for Supervisors class, a 24-week leadership training class, meets every other week for a half-day and is designed to develop future leaders with skills not typically taught within companies. It also hosts several peer groups for CEOs and human resources professionals to connect and learn from one another.

“Last summer, we surveyed 30 manufacturers. Collectively, they estimated they were missing out on at least $450 million in revenue because of the labor shortage, so that’s a primary reason we’re focused on developing workforce,” Cuperus said. “Manufacturers are trying to grow, so they’re increasingly looking at automation and workforce development options instead of solely relying on increasing headcount in today’s hiring landscape.”

Automation-related investments don’t have to be big-ticket items, he added.

“It doesn’t have to be robotic. It can be an app on a phone or a spreadsheet, and it doesn’t have to cost a lot to save a lot of time,” he said. “Sometimes it does, but it doesn’t have to.”

MTS does a great job of “right sizing” an automation plan, Reisenauer said.

“In a tight labor market, one thing you do to get more efficient is put people where they’re good and automate areas that are really labor intensive where people honestly prefer not to work. It’s easy to come in with a grand plan, but if you can’t do more of a crawl, walk, run, most companies won’t take the leap. MTS helps you step into it the right way.”

Many manufacturers still aren’t aware the MTS service exists, Larson said.

“We’re excited to give these services more visibility along with the entire industry,” he said. “Manufacturing is kind of out of sight, out of mind. You don’t know what goes on inside those buildings, but once you do, you realize it’s a dynamic, fast-paced business that works with leading-edge technology.”