Entering third generation, family-owned Maguire Iron builds on national reputation for water tower expertise

Oct. 19, 2021

This paid piece is sponsored by the Prairie Family Business Association.

If you’re going to work in the water tower business, it helps to appreciate the world from 150 feet up.

Parker Jones saw that view for the first time recently, after becoming the third generation of her family to join their company — and climb a water tower.

“We were excited to see her willing and excited to climb,” said her father, Gene Jones Jr., the CEO of Maguire Iron.

“It’s a specialized level of construction working 150 feet in the air.”

For more than a century, Maguire Iron has kept water tanks and towers in working order across the country, while evolving in-house design, fabrication and erection capabilities.

Founder Ed Maguire was a traveling entrepreneur with a paintbrush, bringing his unique and challenging service to communities and their water towers across the Upper Midwest.

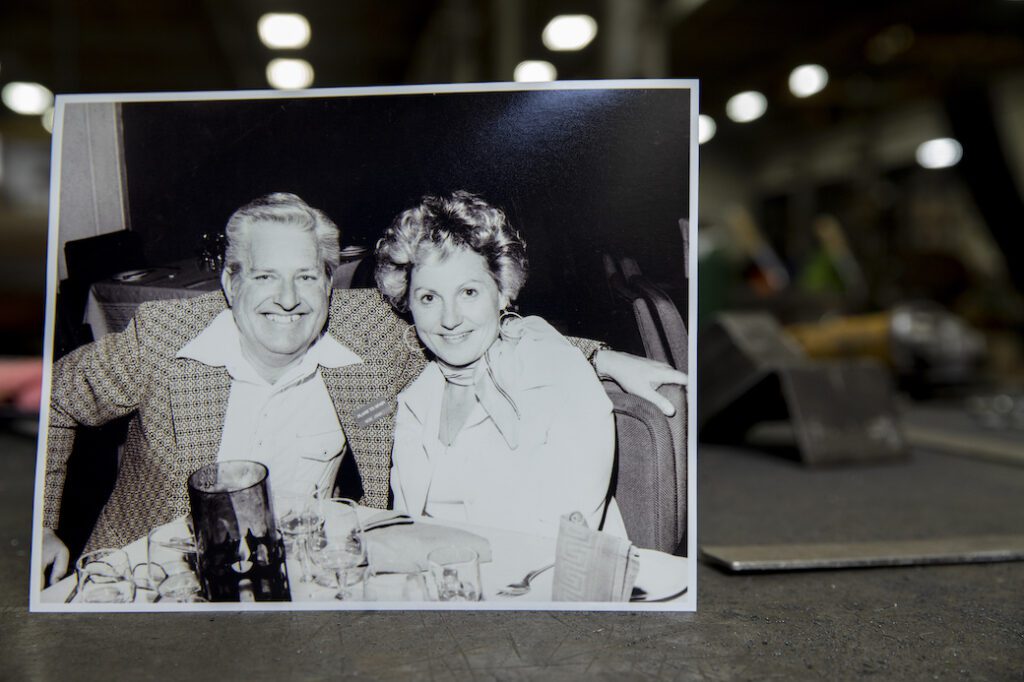

He sold the business in 1958 to Gene Jones Sr., who began his career at age 15 working for competitor Watertower Paint & Repair in Clear Lake, Iowa, before working for Maguire Iron.

Jones’ four sons each worked in the business growing up – tower climbing started at age 12 – and today two continue to work in the business: Gene as CEO and Scott as president.

The headquarters is a five-building campus in north-central Sioux Falls off Minnesota Avenue not far from the Sioux Falls Regional Airport. From there, Maguire serves thousands of communities, rural water districts and private tank owners in 33 states. Of its approximately 160 employees, half are based in Sioux Falls.

The company also recently closed on a property in Texas where it will add an operations facility to serve its growing customer base in the south.

“Our focus is providing opportunities for our up-and-coming leaders as well as the next generation of owners with the Maguire companies,” Gene Jones said.

We sat down with Gene and Scott to learn more about the family business.

How unique is what you do in your industry?

Scott Jones: We are the only one of the major builders in our industry that started as a maintenance company. We believe this is our differentiator. We offer maintenance and new tank services. This makes us an all-in-one provider in the water tank industry.

Gene Jones: The new tank industry is very finite. Everyone is very accomplished and established, so it’s not an industry where you see startups.

Was there a tipping point in the business when your growth began to accelerate?

GJ: We were primarily water tank painters until about 1982 when we bought the assets and contracts of Master Tank out of Slayton, Minnesota, and that’s when we got into the new tank business.

SJ: We started out building two or three tanks a year and progressed to the teens in the 1990s, and by the 2000s through today, we got to where we build around 35 to 40 tanks a year. In addition, we do anywhere from 300 to 400 tank maintenance projects from Canada to the Gulf of Mexico and from the Rocky Mountains to the east of the Mississippi River. Pretty much through the center of the country.

GJ: Then in 2004, we acquired Watertower Paint & Repair, which doubled the size of our painting and repair division, so that was another big growth spurt.

What was your full-time entry into the business like? Was it something you planned to do?

GJ: I graduated from college on Dec. 15, 1984, and started work on Jan. 2, 1985, so I’ve done very little other than work on water towers my entire life. I came back because I wanted to be part of the family business. It was a great opportunity to work with my family in an industry that generally doesn’t see a lot of impact from economic recessions. It’s a pretty stable environment.

SJ: I came back in 1995 after a discussion with my dad. I originally started in sales, and my brother Jeffrey had been working in operations for the company for 10 years. He didn’t want to travel as much as his family grew, so he got out, and I transitioned into operations in 1998.

GJ: Our brother Brad came into the business in the late ’90s after a discussion he and I had in Arizona where I encouraged him to join the rest of the family. Jeffery and I bought dad out in 1993, and then when Jeff got out, Scott and Brad got involved in the ownership. From then, the three of us grew the business for about 20 years until Scott and I bought Brad out in 2019.

What strategies have you found successful in working with your siblings?

GJ: There were plenty of times in the 2000s when we didn’t agree on a direction or decision. We’d sit in my office and voices would rise. People outside the office would hear it, but we always agreed before we came out of the room, we’d tell each other we loved each other, we agreed to disagree, and we’d move forward supporting each other in the decision that was made. I think my mom and dad did a great job of preparing us to work together in a way where we had mutual respect and we wouldn’t just dig our heels in. It worked well. We still have a great family relationship with all of us.

SJ: Plus, we all had our own separate and distinct roles in the business. That made everything work together.

Now that you’ve started including your third generation in the business, how are you approaching that evolution?

GJ: We have family guidelines. If you want to get involved in the business, whether you go to technical school or a four-year college or graduate school, you have to have full-time employment for three years with another business before getting involved with the family business. My daughter Parker was the director of operations for a startup music company for several years before coming to work with us as a product development specialist. Between Scott and I, we have 10 children. Several of them continue to express interest in the business. We are excited that it looks like there will be involvement from our children moving forward.

What kind of culture have you tried to create within the business?

GJ: We focus a lot of attention on our company’s mission, vision and values. We feel strongly about bringing human dignity into the workplace for our co-workers. We believe this is going to make them better spouses and parents if they feel valued in their workplace. We’re grateful that we have great retention in Sioux Falls. Our field position retention is challenging because the work is hard and they are on the road 10 months out of the year. Because of our focus on culture and many new initiatives, our retention in that area has improved greatly in the last five years.

How about taking a look at some of your more memorable projects?

SJ: There have been so many over the years. A water tower is an extremely visible landmark for any city. Many use them as giant billboards so that when you visit or drive through, there is no question where you are. We have built and painted water towers in every color of the rainbow. Recently, we have done a peach basket in Campbell County, Missouri.

We’ve done an ear of corn at the Del Monte plant in Rochester, Minnesota. Just last year, we completed a strawberry tank in Poteet, Texas.

For a lot of places, these become symbols of community pride.

While you primarily work with public sector clients such as municipalities and rural water districts, do you work on the private side as well?

GJ: We’ve done work with Dean Foods, Smithfield, and we’ve worked in the poultry industry. We are always looking for opportunities to expand into different customer bases along with exploring other products and services we could offer.

You were among the founding members of the Prairie Family Business Association. What do you remember about those early days?

GJ: Becoming a member of the Prairie Family Business Association was an opportunity to network with like-minded family business owners in the Sioux Falls community. We were new owners of our family business at that point, and to be in an environment where you could talk to other young family members who were new owners was very valuable.

What does your involvement in the Prairie Family Business Association look like today, or how do you anticipate it evolving?

GJ: Early on, I was involved in more of the curriculum, and then life happened – kids and business growth made it harder to stay active – but we’ve recently reengaged. We are looking forward to hosting this year’s Legacy Tour on Nov 4. And with our third generation coming on board, that brings more energy from the company’s perspective to reengage. Our third generation will have the energy to take it to the next level.

What do you think the future holds for your business? How are you continuing to evolve?

SJ: We will continue to build on our strong culture and history. We will accomplish this through a continued emphasis on making sure our team members are trained, supported and appreciated.

GJ: To continue to grow the company, we are also going to have to lean into innovation and automation. We continue to look at opportunities to automate certain areas of our business. We will always need quality skilled team members to do the work, but doing it in a way where we can leverage automation is going to be a game-changer going forward for the companies that embrace it.

Prairie Family Business Association helps family businesses thrive through generations by providing a resource network for family business success.