Learning lean methods can lead to savings, improved culture

Feb. 28, 2018

This piece is presented by the USD Beacom School of Business executive education program.

The right approach to process improvement can lead to success in any industry. But first, it’s essential to learn the right techniques.

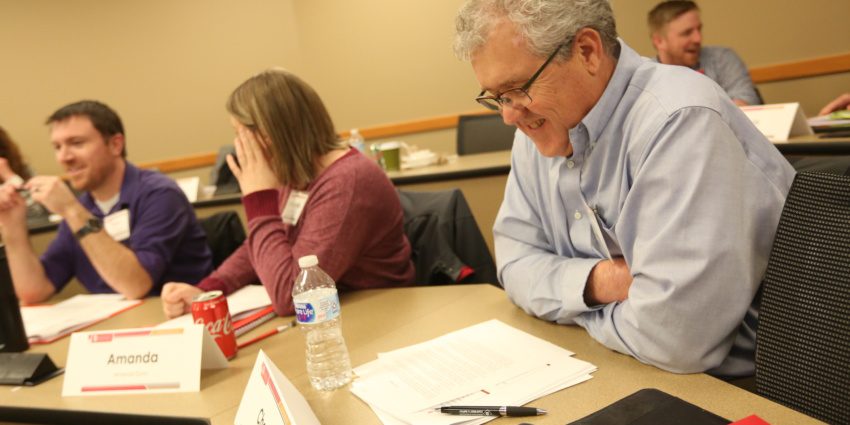

A two-day program April 12 and 19 from the USD Beacom School of Business executive education program will present methodologies ideally suited to helping leaders in any industry develop lean processes to dramatically increase profit and competitive advantage.

To learn more and register, click here.

The course is taught by Dan Tracy, a professor of decision sciences at USD, who has provided consulting services for nine firms yielding more than $7 million in first-year profits.

His students have completed lean projects for more than 150 organizations, resulting in more than $80 million in first-year profits.

If you’d like to be the next to achieve such impressive results, we asked Tracy, who has a doctorate in decision sciences, for tips to get started.

You’ve helped businesses achieve some pretty unbelievable financial gains through lean management. It almost sounds too good to be true. Is there a catch?

There isn’t really a catch, except in what you think you already know. People are caught up in their own assumptions, and what they’re pretty sure they know to be true sometimes isn’t. And that’s something I encourage students to do: Question all assumptions. The worst reason in the world to do something is because that’s the way we’ve always done it. And when you put new eyes on it, a whole new set of options comes to light. And that’s where it sounds too good to be true because, under the assumptions most people continue to operate under, it is. But once you get out from under your own assumptions, there’s a whole new world of possibilities out there.

You shouldn’t expect to have unbelievable financial gains over and over. As you move down the lean path, the gains get thinner. But then you find it in technology, you enter a new market or you introduce a new product. And in that, you introduce waste, because we’re not good at stuff the first time, and it’s a whole new opportunity. It’s a never-ending journey. An author phrased it well: It’s a race without a finish line, and the faster you go the more sustainable, competitive advantage you can achieve.

What’s the first step for a company trying to begin its lean journey?

It’s probably to talk to somebody really knowledgeable about lean who can look at the organization and help you start to see the waste and to teach you a few basic principles and tools. Then you can eventually take it on your own and start to get a culture change where you’re really always looking for the bigger, better way to do things. Once that gets embedded into your culture, it becomes infectious.

What are some common challenges businesses face with lean implementation, and how do you suggest addressing them?

The greatest challenge is it becomes a flavor-of-the-month program and it doesn’t have support because it is all about changing the way people think and changing the culture. Some of the most difficult groups to work with are the ones who have been at a place a long time. They’re convinced because of experience they know more than everybody. The other group is those highly educated in their field — because they’re convinced they know more than everybody else. Sometimes, the appropriate thing is to let someone go. You make your biggest critic your biggest cheerleader or you make them gone. It’s sometimes really that simple. It becomes very real very fast.

What are some strategies for influencing internal support of lean efforts?

If you’re working with a firm that really has never done anything meaningful in terms of lean, it’s all about the first project. It has to be one that has some impact, and it has to be successful because, in a firm that’s never done anything with lean, the firm will be filled with naysayers. “This is just a fad. We’ve seen this stuff before.” And so you’ve got to make those naysayers your biggest cheerleaders by getting them involved with the first project and have it be mind-blowingly successful. And that’s usually pretty easy because there’s so much waste embedded. You have that first big bang of a project, and then you share those successes with everybody and show those financial gains and explain “we can continue to do this. And if we can do this in production, we can do it in HR and payroll and billing and sales and then across the supply chain where we’re starting to see real money.”

Who should consider taking your executive education course?

Anybody who’s truly interested in improvement — because it can be implemented from anywhere within the company: frontline, middle management, executive suite. How difficult it is depends on where you start. If it starts in the executive suite, that’s probably the best case because they can provide leverage to make certain things happen. They can commit resources. If you start in the middle, you have to convince above and below you.

And the course can apply regardless of where you are in lean. If you’re well into lean, you’ll take something away from this. I’ve built time in the schedule to spend part of the days talking one-on-one about your own situation, so you’ll receive some high-level insight. I don’t have anything to gain or lose. It’s pretty easy to trust me, and I can provide a pretty unbiased look at things.

The two-day course, Profitable Process Improvement: Lean Management for Any Industry, is held at the University Center in Sioux Falls. To register, click here.

Business enhances employee negotiating skills with one-day course