Pork producer-owned company plans to build $500M Sioux Falls facility

June 14, 2021

Wholestone Farms, an entity owned by regional pork producers, plans to build a more than $500 million pork processing facility in Sioux Falls.

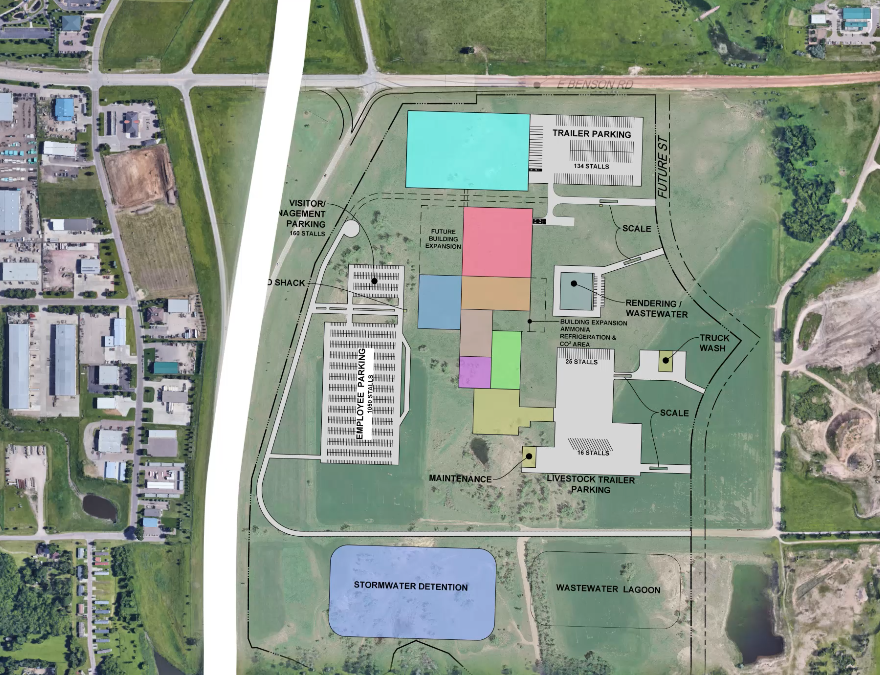

Wholestone has exercised an option to purchase 170 acres in northeast Sioux Falls near Benson Road and Interstate 229, near the new Gage Brothers Concrete Materials location.

Assuming necessary permits are granted and construction stays on track, the facility would open in 2025 and initially employ more than 1,100 people.

“Wholestone is made up of roughly 200 family farms, pork producers, farmers throughout the Midwest, and 70 of those owners live within a 50-mile radius of Sioux Falls,” Wholestone CEO Scott Webb said.

“We need another plant. The Sioux Falls plant is a more ideal location for the ownership group.”

Wholestone began in 2016 as a vision of Minnesota-based Pipestone and the producers it serves. A 75-year-old business that began as a large-animal veterinary practice, it evolved to add include management of sow farms. Its services today include production-driven research, nutrition management, animal health, record keeping and marketing services designed around supporting family farming operations.

Forming a producer-owned processing plant became the next step in the company’s evolution and led to acquiring a Hormel plant in Fremont, Neb.

“We’re small-town farm kids that work at a clinic and work for a lot of farmers and are very, very tightly knit,” said CEO Dr. Luke Minion, who lives in Sioux Falls and also serves as board chair of Wholestone.

“Wholestone Farms is a partnership. I have 220 partners in Wholestone Farms, and that’s an awesome statement to make together.”

The Fremont plant is owned by the producers who supply hogs to it. The group collectively farms 500,000 acres of crop ground and raises 12 million pigs annually. The plant currently operates on one shift and processes 2.8 million head a year, though the plan is to double it in 2023 and do a second shift.

“The word has got out with other independent producers who want to join, and that represents probably another 8 million pigs, but we can’t bring them in until we have more market access,” Webb said.

In Sioux Falls, Wholestone is proposing a facility that initially would process 3 million hogs annually on an eight-hour shift.

The city, however, voiced reservations about the project.

“To be frank, we are facing historic housing challenges right now,” Mayor Paul TenHaken said in a statement provided to SiouxFalls.Business.

“In this unique environment, our employers are also facing critical hiring challenges as we have strategically added thousands of new jobs in recent months. Under normal circumstances, the addition of 1,000 more jobs would be an enormous win for the city of Sioux Falls, yet these are not normal circumstances. While I have been and continue to be supportive of value-added agriculture investments in our region, I have a duty to note the challenges currently being faced within our community at this time.”

The jobs

The positions at Wholestone would be similar to those at Smithfield, which employed 3,700 according to a report from a year ago and works with 550 family farmers to supply the plant.

About 1,000 of the jobs at Wholestone would be people working in the plant, with 50 to 100 additional office and administrative roles.

Because the plant is still years from opening, Wholestone has not set wages but said they will be competitive and include a full benefits package.

“All the robotic technology that’s available will be employed,” Webb said. “There will be some traditional knife work because there are no robots to do that, but the ergonomically difficult jobs will be done by robots.”

The facility itself will be one story, with what the company called state-of-the-art locker rooms, a lot of natural light and a modern cafeteria.

“We’ve done that in Fremont,” Webb said. “Our locker rooms look like what you’d see in a modern middle or high school, and our cafeteria seats 600, and one whole wall is all glass. So there’s light coming in, big-screen TVs, so we’ll employ all that. We’ll have an ergonomic training area on-site, possibly a gym on-site, and that’s not typical in most plants. We strive to be here in Fremont, and we will in Sioux Falls, to be the employer of choice not only in the community but in the industry.”

The location

The location in northeast Sioux Falls was strategically selected, Webb said. Wholestone has had an option on it for several years. The plan is to close on the purchase later this summer.

“Largely, it’s outside the city, it’s zoned as an industrial setting and … it’s convenient for trucks coming in,” Webb said. “Access off the interstate is ideal for a plant like this where you’re going to have 100-plus incoming trucks with live animals coming in per day and probably 120 to 130 finished-product trucks going out.”

The interchange of Benson and I-229 is scheduled for improvement in 2023, with increased capacity and an overpass reconstruction.

Other surrounding land uses include gravel pits, industrial parks and the Sioux Falls wastewater treatment plant.

Wholestone also plans to build a $45 million wastewater treatment plant as part of its project that “is going to exceed current and future compliance limits from the state and EPA,” said Steve Watson, a development strategist at ISG, which has civil and wastewater engineering teams working on the project.

It also will include a modern rendering facility, designed with technology and operational practices that significantly reduce odors compared to older facilities, Wholestone said. Those include technologies such as wet scrubbers, thermal oxidation and covered treatment lagoons.

Webb, whose career includes serving as vice president of food service business development at Smithfield Foods and vice president at Seafood Triumph Foods when it built a modern facility in Sioux City, has experience with the newer technology, which he said “pretty much eliminates the odor … and the technology has gotten even better.”

Producer impact

For producers, access to income derived from processing their hogs can be a game-changer, Webb said.

“If you’re an independent farmer today selling pigs to a packer, it’s difficult to be financially sustainable for the long term,” he said. “By participating in the margins on the processing side, it enables them to be sustainable for the long term.”

For farmers such as John and Linda Jones, who began farming in 1977 south of Mount Vernon, the relationship both with Pipestone and now Wholestone allows them “to have the pig from the semen to the pork chop,” Linda Jones explained.

“There’s a lot of pride knowing you are making good food for people. It’s going to be a really good plant managed by really good people. Wholestone isn’t just a company. It’s a company with a conscience. All the people delivering pigs are the same people you run into at school, at church, in the grocery store. We are your neighbors.”

Because the producers are part of the pig’s life from beginning to end, there’s an added level of transparency, John Jones added, envisioning scanning a pork chop label in a grocery store and then seeing the farm where the pig was raised in a humane manner.

“I’m really proud of them for keeping us on the cutting edge,” he said. “We never sit still. We’re always trying to take the next step and make ourselves better. Call it fate, call it luck, call it whatever you want, it’s probably the best thing that ever happened to us. The whole relationship has been really a blessing.”

Clint Overskei of Nunda also runs a generations-old farm and said he thinks of the relationship with Wholestone as a way to continue the operation.

“This is a legacy project,” he said. “Generational choices. We don’t think by the next quarter or two, it’s generations, and what’s exciting is this is a project where producers involved will be affected for the next couple generations down the line. It’s an opportunity to really expand the family farm, so to speak, beyond the barns.”

Next steps

The earliest construction would start would be later this year, Wholestone leaders said.

Construction is estimated to take 2 1/2 years, meaning the soonest the plant would come online is 2025. That’s about the same time CJ Foods USA Inc. is expecting to open its Asian food production facility in northwest Sioux Falls, bringing more than 600 jobs.

Wholestone expects “some pushback” to having two packing plants in the same town, Webb said.

“I think that’s probably a given — even if we do everything right, which we plan to do, as far as water quality, water discharge, odor control.”

The company is open to “considering strategic partners” to its business plan, he added.

That would be similar to how operations started in Nebraska. While the producers of Wholestone own the Fremont facility, meat is processed for Hormel. It will begin to be sold to the broader marketplace as well starting next year.

“We are open to a strategic partner in this process, whether that strategic partner is someone already operating there or someone else,” Webb said. “They won’t have anything to do with supplying the hogs, but they might buy product out of the plant.”

Minion points to his residency in Sioux Falls as a sign the company is invested here too, he said.

“I love the town, I love being a resident, and I care deeply about the project being everything I want to be proud of – that means the odor, the workforce, the appearance,” he said. “This isn’t some foreign-owned group, and not to say that’s bad because I don’t believe it is, but this is me and the town I live in and 100 farmers who travel to Sioux Falls frequently, and this is really important we do it right. And we will do it right.”

Anticipated questions

Wholestone also released responses to anticipated questions.

How might Wholestone Farms support community housing initiatives?

Wholestone Farms will be a significant, new employer. We’re sensitive to the housing needs of the community and our future employees. With a minimum of three years to plan for our project, we’re prepared to help the community leverage the increased tax base that will be realized as a result of our project to help provide for additional housing support. There are a multitude of ways to support the housing needs in the community, and our team is open to those ways as determined best by the Sioux Falls community. We want to be part of the solution and would challenge other major employers in Sioux Falls and the region to join us in this effort.

How will the company manage its wastewater?

Wholestone Farms is committed to being a good steward of the environment. We plan on investing over $45 million in a state-of-the-art wastewater treatment system that will exceed current and future compliance limits set forth by the EPA and the state of South Dakota. This includes accounting for significant reductions of total nitrogen — including ammonia — and phosphorous. Additionally, the wastewater system will be designed to capture biogas and reduce overall carbon emissions of operations, while managing air quality and minimizing odor.

System reliability and on-site stormwater management will be paramount, including stopgap measures to virtually eliminate the impact of upset events including those resulting from major rain events.

How will you manage odor?

The wastewater system will include covered lagoons. It will be designed and maintained with the latest technologies to minimize odor. Livestock delivery trucks will also be scheduled and staged to minimize odor. A truck wash is also planned on-site.

Wholestone Farms’ entire operation will be designed to exceed the Title V air permitting requirements for the state of South Dakota. Our design will incorporate wet scrubbers and thermal oxidation technologies for emissions and odor control. These technologies, combined with good management practices, will provide many distinct advantages to older facilities.

What environmental considerations are being accounted for in your site design?

The site surrounding the new facility will include low-impact design features such as bioretention cells, vegetative swales, native plantings, buffer strips and other green solutions that result in cleaner air, water and improved habitat. While the surrounding land uses are industrial in nature, our farmer owners are sensitive to designing an operation that is environmentally conscientious.

Community engagement

Wholestone Farms will be an active and engaged corporate citizen. We intend on setting up a new office in Sioux Falls and engaging with civic, business, environmental and nonprofit leaders well in advance of commencing construction of our facility. We have every intention of working closely with groups such as, but not limited to, Lutheran Social Services, the Multi- Cultural Center, Sioux Falls School District and other stakeholders in an effort to provide future employees and their families the resources necessary to optimize their full potential in the community. Wholestone Farms has a rich tradition of being engaged and supportive of area nonprofits in the communities where we operate.

To learn more about Wholestone Farms, click here.