Tru Shrimp finds momentum with revamped plan, new opportunities

This paid piece is sponsored by South Dakota Biotech.

Tru Shrimp, a Minnesota-based company that aims to produce a cleaner, safer, better-tasting shrimp, hopes to break ground on its new facility in Madison this year after a series of encouraging developments.

While the pandemic presented challenges in terms of potential investors or business partners traveling to the company’s pilot-scale operation in Balaton, Minn., 2020 also brought significant breakthroughs behind the scenes.

“Our team found a way to reconfigure our biofiltration process to make the biofilters more effective, so they can handle a greater load of nitrogen plus it turned out to be more efficient and less costly from a capital perspective,” president and CEO Michael Ziebell said.

Instead of beginning with a harbor that can produce 10 million pounds of shrimp and cost an estimated $500 million, the company has shifted to a harbor with 36 tidal basins capable of producing 1.4 million pounds annually.

That, combined with the enhanced efficiency found in the process, led to a $100 million investment goal, “which is much more palatable to people,” Ziebell said.

That’s proving true already. After a series of virtual meetings with investors, one held in person in February “was our most successful event to date in South Dakota, and we’re going to do it again,” he said.

The next investor information sessions is March 25 from 5 to 7 p.m. at The District. Register through the company’s website though walk-ins are welcome. If you can not make the 25th, the company offers virtual presentations frequently and you can again register through the company website; www.trushrimpcompany.com.

“We will serve our shrimp, provide a formal presentation, have a question and answer session and a chance to visit with everyone,” Ziebell said.

Tru Shrimp’s foundation is Marshall, Minn.-based Ralco Nutrition, an animal and agronomy nutrieint conversion technology health company that has offices worldwide.

In the late 2000s, owners Jon and Brian Knochenmus were visiting Ecuador – a world leader in shrimp pond aquaculture – and found local shrimp farmers were using Ralco products to fight disease in shrimp, with anecdotal evidence they were working.

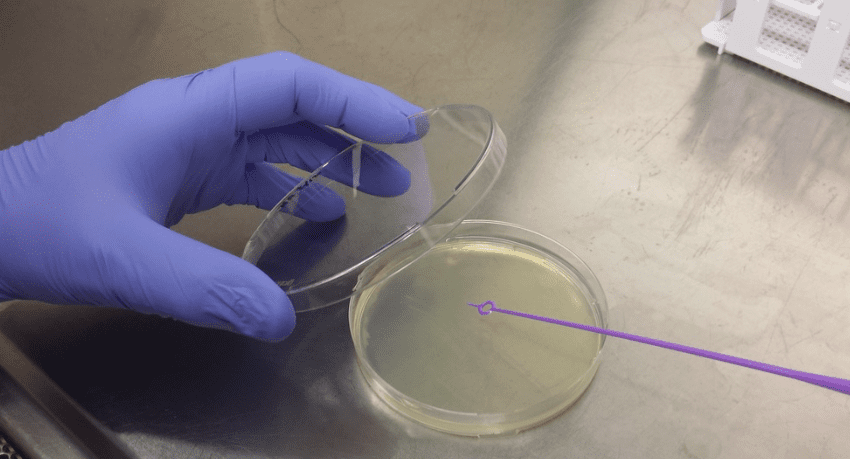

Ralco acquired licensing rights to technology from Texas A&M University in 2014 to grow shrimp indoors in shallow water. The tru Shrimp division of Ralco was formed the following year and began scaling up a “Tidal Basin” to validate the technology in a lab constructed in Balaton, Minn.

A pilot production facility – Balaton Bay Reef– started construction in 2017 in Balaton, Minn., and was commissioned in August 2018.

The company committed to expanding its production in Madison, S.D. later that year and began seeking investors.

A key development in the last year involves a major deal in the making. Tru Shrimp is working with Gordon Food Service, a $14 billion, 120-year-old food service distribution company, to distribute to Canada and the eastern U.S.

“Our conversation started in the fall of 2019, got interrupted by COVID and then picked up again last fall and by December we had signed a letter of intent that will lead to a definitive supply agreement,” Ziebell said.

Gordon Food Service is committing to buy tru Shrimp’s entire shrimp production for the next 10 years, he said.

“Their comment is, ‘You’ll never outproduce what we can sell,’ so that’s a big thing for us. The shrimp are sold, it’s going to be a premium segment and it’s been fun to work with them because they get it,” Ziebell said.

The shrimp then will be distributed to fine dining restaurants and high-end supermarkets, he said.

“And the largest shrimp will be fresh, never frozen, which is a big competitive advantage.”

Tru Shrimp also will sell direct to consumers through its website.

“It’s always been our dream to build a website where people can buy shrimp online, and we know there are people who are willing to pay for the level of quality, safety and sustainability that we’re providing,” Ziebell said.

The other unique market opportunity for tru Shrimp exists with chitosan, which is made by processing the chitin found in the shells of shrimp.

The tru Shrimp facility will produce 2,400 kilograms of chitosan annually and “we’re really starting to confirm the value of it,” Ziebell said. “We’re targeting the highest form of chitosan for medical-grade use and the end markets are substancial.”

Chitosan can be put on the surface of the body or into the body with no toxic effects, he said.

“It will stop bleeding almost instantaneously, it’s a natural antibiotic and because it’s a natural polymer it’s used for scaffolding such as in the esophagus,” he continued.

“They’re using it for tissue engineering where they are 3D-printing tissue and organs and the foundation of that is chitosan. So we have a chance to build this enterprise in such a way that not only are we producing shrimp, but their shells are allowing us to produce chitosan and that value likely will exceed the value of the shrimp itself.”

Tru Shrimp is working with a team to help it navigate the process of taking raw tissue and turning it into chitosan.

“Then we can apply to the FDA to become a supplier,” Ziebell said.

The plan is to break ground in Madison before the end of the year. Once that occurs, it could be up to 22 months before the first shrimp harvest.

Gordon Food Service “wants the shrimp as fast as we can get it to them,” Ziebell added.

“And the people of Madison, the people of South Dakota have been very patient with us as we’ve tried to work through funding, which was harder than we imagined.”

Bank of America is now serving as the company’s investment bank and there has been strong support from individual investors with agriculture backgrounds, he said.

The Madison facility will be expandable, with enough land to at least double in size.

“We’re excited to see tru Shrimp is finding such solid momentum,” said Joni Johnson, executive director of South Dakota Biotech.

“Biotechnology itself aims to help both feed and heal the world, and tru Shrimp is positioned to be an impressive example of how one company can do both.”

To learn more about tru Shrimp, click here.

To get connected to the growing South Dakota biotech industry, click here.