With robots, UV light, Avera starts reusing N95 masks

April 10, 2020

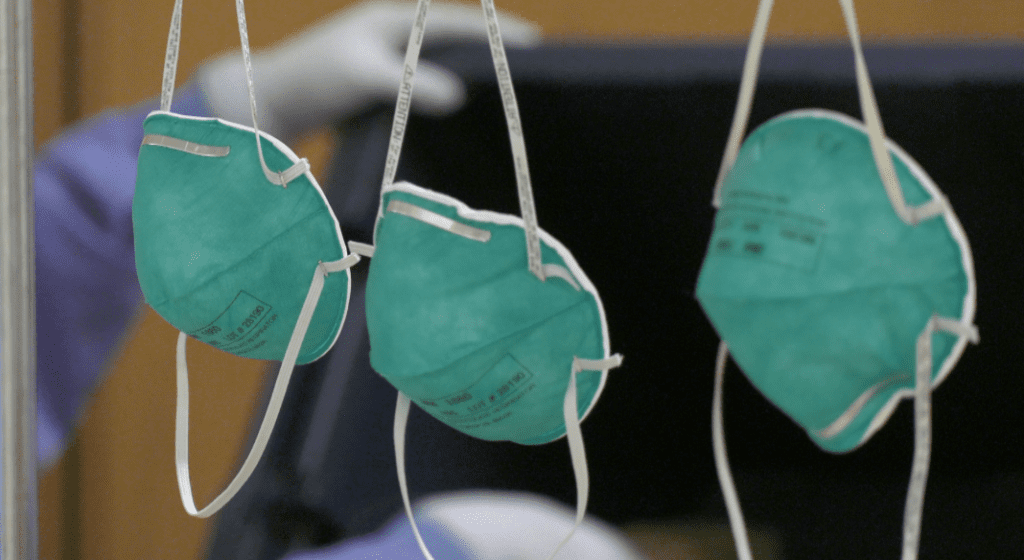

They look like masks hanging from a clothesline.

But these N95 respirators are about to get flooded with ultraviolet light, cast from a robot, as part of a new daily sanitization process at Avera McKennan.

Typically, these masks are not reused. But given the shortage of them worldwide as front-line health care workers require them for protection from COVID-19, the Centers for Disease Control & Prevention recently “challenged organizations and health care facilities to find innovative ways to extend the use of it,” said Sandy King, director of operative services at Avera McKennan.

“So our vendor, Xenex, the UV light partner we use, and the N95 companies we use developed a protocol that would help us extend the life of that mask five times. That’s a huge PPE (personal protective equipment) savings.”

UV light has been used for centuries to disinfect hospital supplies, King said. In 2016, Avera bought two robots that emit ultraviolet light. They’re now being pressed into service to help disinfect the masks daily.

“Ultraviolet light has been scientifically shown to shatter the genetic material inside of virus, so they can’t replicate. Bacteria and virus love to live on surfaces — human surfaces and inanimate surfaces — so the UV light was purchased to help sanitize the operating rooms.”

The new reuse system went fully operational last week after a short pilot period. Staff in areas such as the emergency department and intensive care unit who regularly use N95 masks now go to a designated collection point with their mask at the end of a shift. They put the mask in a brown paper bag, and it goes into a sealed tote.

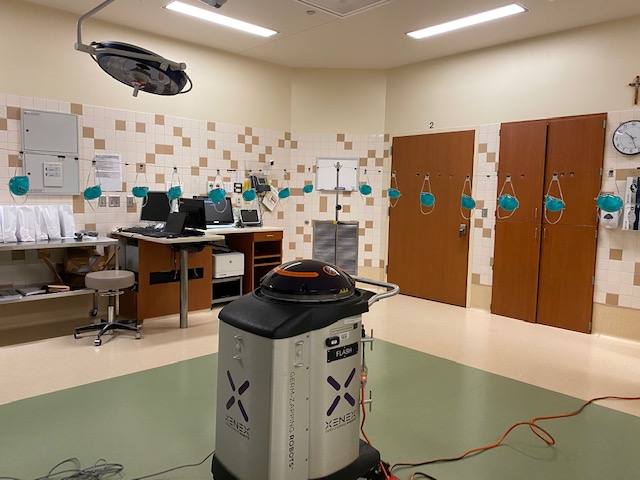

“At various times through the day, our sterilization staff will go to these designated areas, pick up the totes and bring them to disinfection,” King said. “We have it set up in one of our operating rooms. It’s a super bright light. We cover the windows. They’re hung on something similar to a clothesline. The front of the mask faces the ultraviolet light robot, so it gets maximum exposure.”

The system can sanitize 80 masks in about five minutes.

When the process is done, staff put each mask in a white bag with the employee’s name on it, and they’re delivered back to the unit. A check mark is placed on each, and each is entered into a computerized log to make sure no mask is used more than five times.

“This week, we went external with it, so all our Avera facilities have the capacity to send their N95s in,” King said.

“It’s the most important piece of equipment our health care providers need. We feel definitely much better, and I think our providers probably are more at ease not having to worry about whether they have an N95 mask for their shift tomorrow. It’s so important.”

The process “takes a village,” she added.

“The real heroes are our staff in sterilization. They are the ones that helped get this up and rolling, and they’re the ones on the front lines just like the health care workers in making sure we provide a safe alternative to our providers.”